Impact wrench not strong enough? You’re not alone. Many people face this issue, and it can be incredibly frustrating.

Understanding the necessary torque for an impact wrench to be effective

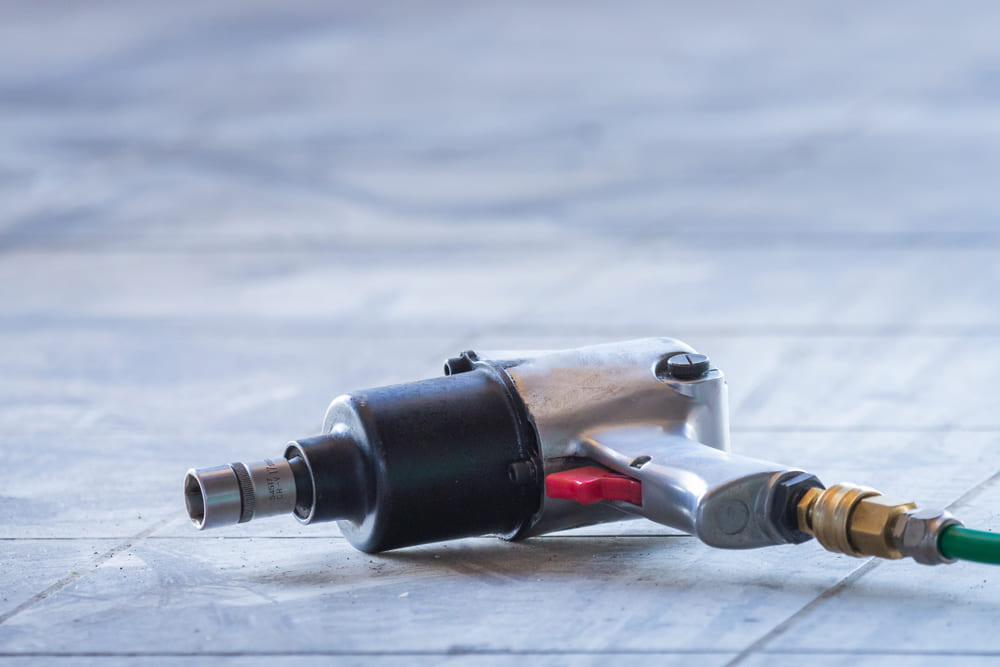

An impact wrench is a powerful tool, but it’s only as good as the torque it produces. The torque required for an impact wrench to be effective depends on the task at hand.

For example, automotive lug nuts typically require between 80 and 100 ft-lbs of torque, while heavy-duty applications like suspension work may require up to 250 ft-lbs.

If your impact wrench isn’t producing enough torque, it may struggle to complete the task, leaving you frustrated and wondering why your tool isn’t performing as it should.

Solutions for addressing low torque in impact wrenches

If you find yourself thinking, “my impact wrench is not strong enough,” don’t worry. There are several solutions to address low torque in impact wrenches.

- Check the air pressure: If you’re using a pneumatic impact wrench, make sure the air pressure is set correctly. Low air pressure can result in reduced torque output. Refer to the manufacturer’s guidelines for the recommended air pressure settings.

- Inspect the hoses: Ensure that there are no kinks or leaks in the air hoses. These issues can reduce the air pressure reaching the tool, resulting in a loss of torque.

- Clean and lubricate the tool: Regular maintenance is crucial for optimal performance. Clean the tool thoroughly and apply lubricant to the moving parts as recommended by the manufacturer.

- Upgrade to a more powerful tool: If you’ve tried the above solutions and your impact wrench still isn’t strong enough, it may be time to invest in a more powerful tool. Consider upgrading to a model with a higher torque output to handle the tasks you need to complete.

Mismatched sockets: a common mistake to avoid

One common mistake that can lead to an impact wrench not being strong enough is using mismatched sockets. Using the wrong size or type of socket can result in poor contact between the socket and the fastener, reducing the torque transferred to the fastener.

To avoid this issue, always use the correct size and type of socket for the task at hand. Impact sockets are specifically designed for use with impact wrenches and are made from a more robust material to withstand the high torque forces.

Using regular sockets with an impact wrench can result in damage to both the socket and the fastener.

Purchasing the right wrench size and kind to avoid costly mistakes

Impact wrench not strong enough? This issue could be due to using the wrong wrench size or type. When purchasing an impact wrench, it’s essential to choose the right size and kind to avoid costly mistakes and ensure optimal performance. Let’s explore some factors to consider when selecting an impact wrench.

- Consider the tasks you’ll be performing: The size and type of impact wrench you need will depend on the tasks you plan to use it for. For example, a 1/2-inch drive impact wrench is suitable for automotive work, while a 3/8-inch drive is better suited for lighter tasks.

- Choose between cordless, electric, and pneumatic: Impact wrenches come in three main types: cordless, electric, and pneumatic. Each type has its pros and cons, so consider which one best suits your needs. Cordless impact wrenches offer portability and convenience, electric ones provide consistent power without the need for an air compressor, and pneumatic wrenches deliver the highest torque output.

- Look for adjustable torque settings: To ensure your impact wrench is strong enough for various tasks, choose a model with adjustable torque settings. This feature allows you to control the torque output, ensuring you have the right amount of power for each job.

Air compressor size requirements for impact wrenches

If you’re using a pneumatic impact wrench, the size of your air compressor plays a crucial role in determining whether your tool is strong enough. An air compressor that’s too small won’t provide enough air pressure, resulting in reduced torque output. Here are some factors to consider when choosing an air compressor for your impact wrench:

- Check the air consumption (CFM) rating: The air consumption, measured in cubic feet per minute (CFM), indicates the amount of air required to operate your impact wrench efficiently. Make sure your air compressor can provide enough CFM to meet your tool’s requirements.

- Consider the tank size: A larger tank size allows your air compressor to store more air, ensuring a steady supply for your impact wrench. If the tank is too small, the compressor will need to run continuously to keep up with the air demand, which can lead to reduced torque output.

- Choose the right horsepower (HP): The horsepower of your air compressor directly affects the air pressure it can generate. A higher horsepower compressor will provide more air pressure, ensuring your impact wrench has enough power to complete the task.

How the hammering mechanism works in an impact wrench

The key to an impact wrench’s power lies in its hammering mechanism. This mechanism allows the tool to deliver a series of high-torque impacts, making it easier to loosen or tighten fasteners. Let’s take a closer look at how this mechanism works.

- The motor: The motor, whether electric or air-powered, provides the rotational force to the impact wrench.

- The hammer and anvil: The hammer is a weighted, rotating component that strikes the anvil, which is connected to the output shaft and socket.

- Impact action: As the motor rotates the hammer, it builds up momentum. When the hammer hits the anvil, it transfers this momentum to the output shaft, creating a sudden, high-torque impact.

- Repeat impacts: The hammering mechanism continues to deliver a series of impacts, providing the necessary torque to loosen or tighten the fastener.

Understanding how the hammering mechanism works can help you troubleshoot issues with your impact wrench and ensure it’s strong enough for the task at hand.

Conclusion: Tips for Ensuring Your Impact Wrench is Strong Enough

If you’re struggling with an impact wrench not strong enough, there are several steps you can take to address the issue. By purchasing the right wrench size and kind, choosing the appropriate air compressor, and understanding how the hammering mechanism works, you can ensure your impact wrench is up to the task.

Remember to maintain your tool, use the correct sockets, and consider upgrading to a more powerful model if necessary. With these tips in mind, you’ll be well-equipped to tackle any job with your impact wrench.